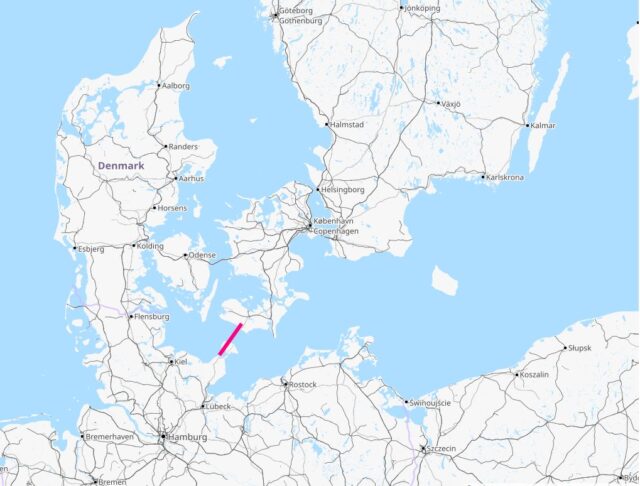

Denmark has built the first element of a tunnel that will connect the German port of Puttgarden to the Danish town of Rödbyhavn. In June 2024, The King of Denmark Frederik inaugurated the first milestone of the tunnel project that is scheduled to open for traffic in 2029. The Fehmarnbelt will be the longest underwater tunnel in the world built both for train and road traffic.

The underwater section of the Fehmarnbelt is 18 km / 11 miles long. There are two undersea tunnels longer than the new construction connecting Denmark and Germany, but both of these longer tunnels were built for rail traffic alone:

- 38 km / 23.6 miles (underwater section) Channel Tunnel between England and France.

- 23 km / 14.5 miles Seikan tunnel between the Japanese islands of Honshu and Hokkaido.

The new Fehmarnbelt tunnel will be a significant long term infrastructure resource for Denmark and to the rest of the Nordic region Norway, Sweden and Finland. Although Nordic countries are not exactly an island faraway from the rest of Europe, the primary land routes between Scandinavia and the continent are cut off by the Baltic Sea. In 2029, together with the Öresund Bridge from Copenhagen to Malmö, Sweden, the new tunnel will allow rail and road traffic between Central and North Europe.

Travel times through the Fehmarntunnel are expected to be 10 minutes by car and 7 minutes by train.

In addition to faster cargo transport, one can expect more train journeys and road trips when travel times from south to north (and vice versa) drop and travel convenience improves. Perhaps one of the last large wilderness regions of Europe, the Arctic Lapland, will see more visitors across its fjells, rivers and fjords as well.

The technique for building the tunnel is exceptional. It will be made of 79 massive concrete elements that are constructed on a purpose built site in Rödbyhavn. Each tunnel element is 217 meters long, with enough width to have five separate tunnels for two rail tracks, two roads, and a service passage.

Here is the ingenious thing in the construction. When a new massive element is ready in the factory, its ends are sealed off, pulled to the sea, it is floating until it reaches its coming resting place, filled with water so that it sinks, moved in its exact millimeter precision position in the tunnel, and the water is pumped out from the element.

Take a look at the video by Femern AS that describes the fascinating process:

DW visited the tunnel construction site in Germany: